Project Description

Initial open pit mining for copper sulphide commenced in 1964 and full mining operations at Kidd Creek started in 1966. Shaft sinking for the No. 1 Mine started in 1969 from 900 ft to 3050 ft currently. For the No. 2 Mine shaft sinking started in 1974, and currently the mine operates between 3050 and 4700 ft levels. No. 3 Mine started operation in October 1990 and currently it operates between 4700 and 6800 ft. levels. To date, 110 million tonnes have been mined at Kidd Creek. To date the total proven and probable reserves amount to approximately 38 million tonnes, which includes 6 million tonnes for No.1 Mine, 1.5 million tonnes for No.2 Mine, 8 million tonnes for No. 3 Mine and 23 million tonnes for Mine D.

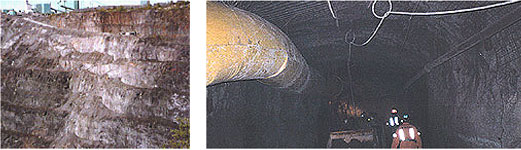

The Kidd Creek deposit is located at the western end of the Abitibi greenstone belt. The deposit has been characterized as a stratiform massive base metal sulphides associated with felsic volcanic rocks. The structural geology in the vicinity of the mine is complex and the massive sulphide deposit lies within a sequence of steeply dipping overturned felsic and mafic volcanic rocks. The near vertical orebody generally strikes north-south and dips steeply northeast to east, however zonal variations and localized reverse dips occur. The predominant types of rock are andesite, rhyolite, sulphides, talc-carbonate and greywacke. The hanging wall and foot wall rocks around the orebody comprising copper stringer and massive sulphide often contain significantly more shistosity than the orebody itself. The rock formations in the mine area have been subjected to complex faulting. A gouge fault strikes north to northwest, and dips 55 to 65 degrees northeast. The gouge fault intersects the ore body at a level of 4600 ft. (46L) at the foot wall, and then dips into the hanging wall at an approximate level of 6800 ft (68L) and is not expected to be encountered in the mine at greater depth, except for localized gouge fault splays.

The mining operations include permanent surface facilities as headframes, surface crusher, fill plants, wastewater treatment, rail lines, buildings and offsite tailings. The undergound facilities include shafts, ramps, drifts, raises, crushers, conveyors, rails, shops, ventilation, drainage, tailings and backfill. The temporary facilities include crosscuts, slots, stopes, pillars, crown pillars and sills. The mobile equipment includes jumbo drills, raise bores, scoop trams and haul trucks. The rock support methods include rock bolts, wire mesh, cable bolts, steel straps, shotcrete, grouting, steel ribs and bulkheads. The instrumentation and monitoring includes macroseismics, microseismics, survey monitors, extensometers and stress cells.

The geomechanics review included structural geology, rock mass stability, rock support methods, instrumentation and monitoring, site review and reporting.

Project Facts

- Location: Timmins, Ontario, Canada

- Owner: Falconbridge Limited, Kidd Creek Mining Division

- Geotechnical Review: Sarafinchin Associates Ltd.

- Project Services: Geomechanics, Geology, Rock Mechanics Review