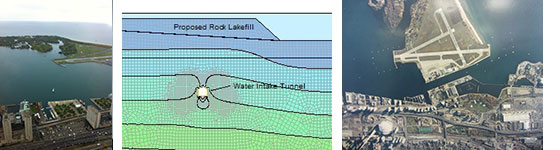

Sarafinchin carried out a computerized numerical analysis to estimate the stress conditions to the existing tunnel section. Stress conditions resulted from alternative rockfill placement configurations above the existing water intake tunnel, located beyond the east end of the Billy Bishop Toronto Island Airport runway and within the Marine Exclusion Zone (MEZ) of Toronto Harbour. TPA considered placing approximately 21,777 m3 of sound grey shale waste rock from the pedestrian tunnel excavation as rockfill within the MEZ. Approximately 3,761 m3 of rip rap cover was also considered as a confining shell material on the underwater slopes of the proposed submerged fill embankment. The proposed rockfill placement configuration had a cross sectional area of about 349 m2. The purpose of the finite element analyses (FEM) was to estimate increases in the maximum compressive and tensile stresses in the existing old tunnel section, based on the selected rockfill configuration. This rockfill was placed some distance from the tunnel section. Initially, only two fill locations were contemplated. However, our findings indicated that greater fill separation from the tunnel should be considered. Six alternative rockfill configurations were also reviewed, with rockfill placed at distances ranging from approximately 5 m to 30 m from the tunnel centerline as per our cross sectional models. Based on geotechnical assumptions in this desktop office study, and subject to field confirmation of the actual subsurface and tunnel conditions, it was our opinion that the estimated maximum compressive and tensile stress increases of the concrete and masonry water intake tunnel section would lessen with a greater distance from the proposed underwater rockfill zone. The percent increases are considered to be negligible beyond 30 m for the modeled rockfill configurations and for a tunnel section in good condition and structurally sound subject geotechnical field monitoring during underwater rockfill and protective shell placement to record the types and quantity of materials, specified physical limits, confirming compliance requirements, and the like.Project Description

Project Facts